What Components and Modules Does the Startup Capacitor Contain?

I. Introduction

In the realm of electrical systems, the startup capacitor plays a pivotal role in ensuring the efficient operation of various devices, particularly electric motors. A startup capacitor is a type of capacitor specifically designed to provide an initial boost of energy to start an electric motor. This article aims to delve into the components and modules that constitute a startup capacitor, exploring its significance in electrical systems and its various applications.

II. Understanding Capacitors

A. Basic Principles of Capacitors

Capacitors are passive electrical components that store and release electrical energy. They consist of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy.

1. Definition and Function

The primary function of a capacitor is to store electrical energy temporarily and release it when needed. This ability makes capacitors essential in various applications, from smoothing out voltage fluctuations to providing bursts of energy in motors.

2. Types of Capacitors

Capacitors come in various types, including ceramic, electrolytic, tantalum, and film capacitors, each with unique properties and applications. The choice of capacitor type depends on factors such as capacitance value, voltage rating, and intended use.

B. Role of Capacitors in Electrical Circuits

Capacitors play a crucial role in electrical circuits by:

1. Energy Storage

Capacitors store energy in the form of an electric field, which can be released quickly when needed. This characteristic is particularly useful in applications requiring short bursts of energy, such as starting motors.

2. Voltage Regulation

Capacitors help maintain stable voltage levels in circuits by smoothing out fluctuations. They can absorb excess voltage during peak loads and release energy during low-demand periods, ensuring consistent performance.

III. What is a Startup Capacitor?

A. Definition and Purpose

A startup capacitor is specifically designed to provide the necessary energy boost to start an electric motor. It temporarily increases the starting torque of the motor, allowing it to overcome inertia and begin operation.

B. Applications of Startup Capacitors

Startup capacitors are commonly used in various applications, including:

1. Electric Motors

In electric motors, startup capacitors are essential for initiating rotation. They provide the extra energy needed to overcome the initial resistance and get the motor running.

2. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems often utilize startup capacitors to ensure that compressors and fans start efficiently, contributing to overall system performance.

3. Other Electrical Devices

Startup capacitors are also found in various other electrical devices, such as refrigerators, washing machines, and power tools, where they facilitate smooth operation.

IV. Components of a Startup Capacitor

Understanding the components of a startup capacitor is crucial for grasping its functionality. The main components include:

A. Dielectric Material

1. Definition and Function

The dielectric material is the insulating layer between the conductive plates of the capacitor. It plays a vital role in determining the capacitor's performance, including its capacitance and voltage rating.

2. Common Types of Dielectric Materials Used

Common dielectric materials include polyester, polypropylene, and ceramic. Each type has distinct properties that affect the capacitor's performance in different applications.

B. Conductive Plates

1. Role in Energy Storage

The conductive plates are responsible for storing electrical energy. When a voltage is applied, an electric field forms between the plates, allowing energy to be stored.

2. Materials Used for Conductive Plates

Conductive plates are typically made from aluminum or copper due to their excellent conductivity and ability to withstand high temperatures.

C. Insulation

1. Importance of Insulation in Capacitors

Insulation is crucial for preventing electrical leakage and ensuring the safe operation of the capacitor. It also helps maintain the integrity of the dielectric material.

2. Types of Insulation Materials

Common insulation materials include plastic films, rubber, and epoxy resins, each chosen based on the specific requirements of the capacitor.

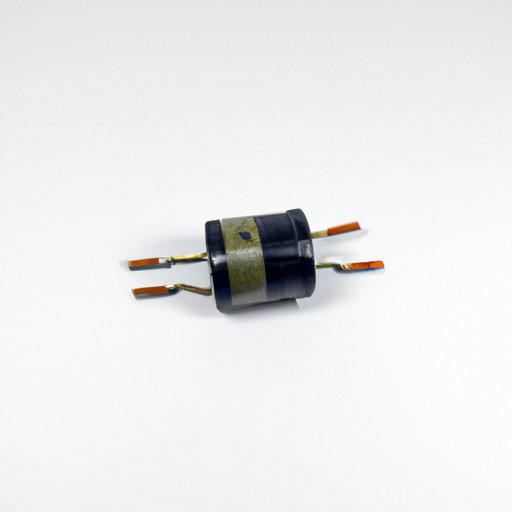

D. Terminals

1. Function and Design

Terminals are the connection points for the capacitor to the electrical circuit. They allow the capacitor to be integrated into various systems.

2. Connection to Electrical Circuits

Terminals are designed for easy connection and disconnection, ensuring that the capacitor can be replaced or serviced as needed.

V. Modules and Design of Startup Capacitors

A. Capacitor Construction

The construction of startup capacitors can vary based on their intended application.

1. Cylindrical vs. Rectangular Designs

Startup capacitors are available in both cylindrical and rectangular designs. The choice of shape often depends on space constraints and the specific requirements of the application.

2. Size and Shape Considerations

The size and shape of a capacitor can influence its performance, including its capacitance value and voltage rating. Manufacturers must carefully consider these factors during the design process.

B. Ratings and Specifications

Startup capacitors are characterized by several key ratings and specifications:

1. Voltage Rating

The voltage rating indicates the maximum voltage the capacitor can handle without failure. It is crucial to select a capacitor with an appropriate voltage rating for the application.

2. Capacitance Value

The capacitance value, measured in microfarads (µF), determines the amount of energy the capacitor can store. Different applications require different capacitance values.

3. Temperature Ratings

Temperature ratings indicate the range of temperatures within which the capacitor can operate safely. This is particularly important in applications exposed to extreme conditions.

C. Manufacturing Processes

1. Overview of How Startup Capacitors Are Made

The manufacturing process of startup capacitors involves several steps, including the selection of materials, assembly of components, and testing for quality assurance.

2. Quality Control Measures

Quality control measures are essential to ensure that startup capacitors meet industry standards and perform reliably in their intended applications.

VI. Types of Startup Capacitors

There are several types of startup capacitors, each designed for specific applications:

A. Permanent Split Capacitor (PSC)

PSC capacitors are used in single-phase motors and provide continuous operation without the need for a separate starting circuit.

B. Capacitor Start Induction Run (CSIR)

CSIR capacitors are used in motors that require a high starting torque. They provide a boost during startup and then disconnect from the circuit once the motor reaches a certain speed.

C. Capacitor Start Capacitor Run (CSCR)

CSCR capacitors are designed for applications requiring both starting and running capacitance. They remain in the circuit during operation, enhancing efficiency.

D. Comparison of Different Types

Each type of startup capacitor has its advantages and disadvantages, making it essential to choose the right one based on the specific requirements of the application.

VII. Applications and Importance of Startup Capacitors

A. Role in Motor Starting

Startup capacitors are critical for providing the necessary torque to start electric motors, ensuring smooth operation and preventing damage to the motor.

B. Impact on Energy Efficiency

By facilitating efficient motor starting, startup capacitors contribute to overall energy efficiency in electrical systems, reducing energy consumption and operational costs.

C. Contribution to System Reliability

Reliable operation of startup capacitors enhances the overall reliability of electrical systems, minimizing downtime and maintenance costs.

VIII. Troubleshooting and Maintenance

A. Common Issues with Startup Capacitors

Startup capacitors can experience various issues, including failure to start the motor, overheating, and electrical leakage.

B. Signs of Failure

Common signs of capacitor failure include unusual noises, burning smells, and visible damage to the capacitor casing.

C. Maintenance Tips and Best Practices

Regular inspection and testing of startup capacitors can help identify potential issues before they lead to failure. It is essential to follow manufacturer guidelines for maintenance and replacement.

IX. Conclusion

In conclusion, startup capacitors are vital components in electrical systems, providing the necessary energy boost to start motors and ensuring efficient operation. Understanding the components and modules that make up a startup capacitor is essential for anyone involved in electrical engineering or maintenance. As technology advances, the future of capacitor technology promises even greater efficiency and reliability, further solidifying the role of startup capacitors in modern electrical systems.

X. References

For further reading on startup capacitors and their applications, consider exploring the following sources:

1. "Capacitors: Principles and Applications" by John Smith

2. "Electrical Engineering: Principles and Applications" by Allan R. Hambley

3. Online resources from electrical engineering websites and forums.

This comprehensive overview of startup capacitors highlights their importance, components, and applications, providing valuable insights for both professionals and enthusiasts in the field of electrical systems.

What Components and Modules Does the Startup Capacitor Contain?

I. Introduction

In the realm of electrical systems, the startup capacitor plays a pivotal role in ensuring the efficient operation of various devices, particularly electric motors. A startup capacitor is a type of capacitor specifically designed to provide an initial boost of energy to start an electric motor. This article aims to delve into the components and modules that constitute a startup capacitor, exploring its significance in electrical systems and its various applications.

II. Understanding Capacitors

A. Basic Principles of Capacitors

Capacitors are passive electrical components that store and release electrical energy. They consist of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy.

1. Definition and Function

The primary function of a capacitor is to store electrical energy temporarily and release it when needed. This ability makes capacitors essential in various applications, from smoothing out voltage fluctuations to providing bursts of energy in motors.

2. Types of Capacitors

Capacitors come in various types, including ceramic, electrolytic, tantalum, and film capacitors, each with unique properties and applications. The choice of capacitor type depends on factors such as capacitance value, voltage rating, and intended use.

B. Role of Capacitors in Electrical Circuits

Capacitors play a crucial role in electrical circuits by:

1. Energy Storage

Capacitors store energy in the form of an electric field, which can be released quickly when needed. This characteristic is particularly useful in applications requiring short bursts of energy, such as starting motors.

2. Voltage Regulation

Capacitors help maintain stable voltage levels in circuits by smoothing out fluctuations. They can absorb excess voltage during peak loads and release energy during low-demand periods, ensuring consistent performance.

III. What is a Startup Capacitor?

A. Definition and Purpose

A startup capacitor is specifically designed to provide the necessary energy boost to start an electric motor. It temporarily increases the starting torque of the motor, allowing it to overcome inertia and begin operation.

B. Applications of Startup Capacitors

Startup capacitors are commonly used in various applications, including:

1. Electric Motors

In electric motors, startup capacitors are essential for initiating rotation. They provide the extra energy needed to overcome the initial resistance and get the motor running.

2. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems often utilize startup capacitors to ensure that compressors and fans start efficiently, contributing to overall system performance.

3. Other Electrical Devices

Startup capacitors are also found in various other electrical devices, such as refrigerators, washing machines, and power tools, where they facilitate smooth operation.

IV. Components of a Startup Capacitor

Understanding the components of a startup capacitor is crucial for grasping its functionality. The main components include:

A. Dielectric Material

1. Definition and Function

The dielectric material is the insulating layer between the conductive plates of the capacitor. It plays a vital role in determining the capacitor's performance, including its capacitance and voltage rating.

2. Common Types of Dielectric Materials Used

Common dielectric materials include polyester, polypropylene, and ceramic. Each type has distinct properties that affect the capacitor's performance in different applications.

B. Conductive Plates

1. Role in Energy Storage

The conductive plates are responsible for storing electrical energy. When a voltage is applied, an electric field forms between the plates, allowing energy to be stored.

2. Materials Used for Conductive Plates

Conductive plates are typically made from aluminum or copper due to their excellent conductivity and ability to withstand high temperatures.

C. Insulation

1. Importance of Insulation in Capacitors

Insulation is crucial for preventing electrical leakage and ensuring the safe operation of the capacitor. It also helps maintain the integrity of the dielectric material.

2. Types of Insulation Materials

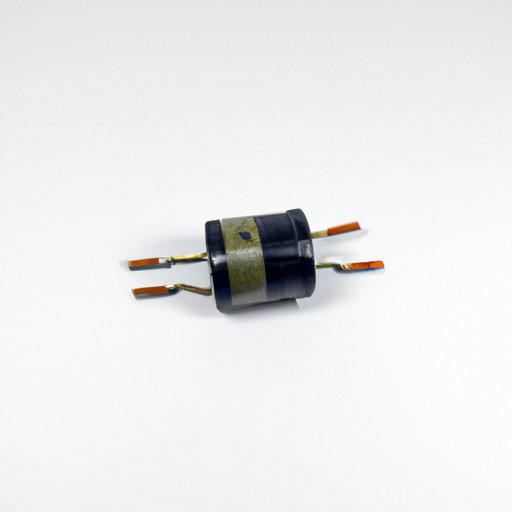

Common insulation materials include plastic films, rubber, and epoxy resins, each chosen based on the specific requirements of the capacitor.

D. Terminals

1. Function and Design

Terminals are the connection points for the capacitor to the electrical circuit. They allow the capacitor to be integrated into various systems.

2. Connection to Electrical Circuits

Terminals are designed for easy connection and disconnection, ensuring that the capacitor can be replaced or serviced as needed.

V. Modules and Design of Startup Capacitors

A. Capacitor Construction

The construction of startup capacitors can vary based on their intended application.

1. Cylindrical vs. Rectangular Designs

Startup capacitors are available in both cylindrical and rectangular designs. The choice of shape often depends on space constraints and the specific requirements of the application.

2. Size and Shape Considerations

The size and shape of a capacitor can influence its performance, including its capacitance value and voltage rating. Manufacturers must carefully consider these factors during the design process.

B. Ratings and Specifications

Startup capacitors are characterized by several key ratings and specifications:

1. Voltage Rating

The voltage rating indicates the maximum voltage the capacitor can handle without failure. It is crucial to select a capacitor with an appropriate voltage rating for the application.

2. Capacitance Value

The capacitance value, measured in microfarads (µF), determines the amount of energy the capacitor can store. Different applications require different capacitance values.

3. Temperature Ratings

Temperature ratings indicate the range of temperatures within which the capacitor can operate safely. This is particularly important in applications exposed to extreme conditions.

C. Manufacturing Processes

1. Overview of How Startup Capacitors Are Made

The manufacturing process of startup capacitors involves several steps, including the selection of materials, assembly of components, and testing for quality assurance.

2. Quality Control Measures

Quality control measures are essential to ensure that startup capacitors meet industry standards and perform reliably in their intended applications.

VI. Types of Startup Capacitors

There are several types of startup capacitors, each designed for specific applications:

A. Permanent Split Capacitor (PSC)

PSC capacitors are used in single-phase motors and provide continuous operation without the need for a separate starting circuit.

B. Capacitor Start Induction Run (CSIR)

CSIR capacitors are used in motors that require a high starting torque. They provide a boost during startup and then disconnect from the circuit once the motor reaches a certain speed.

C. Capacitor Start Capacitor Run (CSCR)

CSCR capacitors are designed for applications requiring both starting and running capacitance. They remain in the circuit during operation, enhancing efficiency.

D. Comparison of Different Types

Each type of startup capacitor has its advantages and disadvantages, making it essential to choose the right one based on the specific requirements of the application.

VII. Applications and Importance of Startup Capacitors

A. Role in Motor Starting

Startup capacitors are critical for providing the necessary torque to start electric motors, ensuring smooth operation and preventing damage to the motor.

B. Impact on Energy Efficiency

By facilitating efficient motor starting, startup capacitors contribute to overall energy efficiency in electrical systems, reducing energy consumption and operational costs.

C. Contribution to System Reliability

Reliable operation of startup capacitors enhances the overall reliability of electrical systems, minimizing downtime and maintenance costs.

VIII. Troubleshooting and Maintenance

A. Common Issues with Startup Capacitors

Startup capacitors can experience various issues, including failure to start the motor, overheating, and electrical leakage.

B. Signs of Failure

Common signs of capacitor failure include unusual noises, burning smells, and visible damage to the capacitor casing.

C. Maintenance Tips and Best Practices

Regular inspection and testing of startup capacitors can help identify potential issues before they lead to failure. It is essential to follow manufacturer guidelines for maintenance and replacement.

IX. Conclusion

In conclusion, startup capacitors are vital components in electrical systems, providing the necessary energy boost to start motors and ensuring efficient operation. Understanding the components and modules that make up a startup capacitor is essential for anyone involved in electrical engineering or maintenance. As technology advances, the future of capacitor technology promises even greater efficiency and reliability, further solidifying the role of startup capacitors in modern electrical systems.

X. References

For further reading on startup capacitors and their applications, consider exploring the following sources:

1. "Capacitors: Principles and Applications" by John Smith

2. "Electrical Engineering: Principles and Applications" by Allan R. Hambley

3. Online resources from electrical engineering websites and forums.

This comprehensive overview of startup capacitors highlights their importance, components, and applications, providing valuable insights for both professionals and enthusiasts in the field of electrical systems.