What are the Popular Fan Capacitor Product Types?

I. Introduction

Fan capacitors are essential components in various electrical systems, particularly in fans and motors. They play a crucial role in enhancing the performance and efficiency of these devices. Understanding the different types of fan capacitors and their applications can help consumers and technicians make informed decisions when selecting or replacing these components. This article aims to provide a comprehensive overview of fan capacitors, their types, features, selection criteria, and maintenance tips.

II. Understanding Fan Capacitors

A. What is a Capacitor?

At its core, a capacitor is an electrical component that stores and releases electrical energy. It consists of two conductive plates separated by an insulating material, known as a dielectric. The basic principle of capacitance is the ability of a capacitor to store an electric charge. When voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy.

Capacitors play a vital role in electrical circuits by smoothing out voltage fluctuations, filtering signals, and providing the necessary phase shift in alternating current (AC) applications. In the context of fans, capacitors are crucial for starting and running the motors efficiently.

B. Specific Function of Fan Capacitors

Fan capacitors serve two primary functions: starting and running. Starting capacitors provide the initial boost of energy needed to start the motor, while running capacitors maintain the motor's operation by ensuring a consistent flow of energy. By enhancing the performance of fans, these capacitors contribute to improved efficiency, reduced energy consumption, and extended motor life.

III. Types of Fan Capacitors

A. Permanent Split Capacitor (PSC)

**1. Description and Working Principle**

Permanent Split Capacitor (PSC) motors are designed with a capacitor that remains in the circuit during both starting and running phases. This type of capacitor is permanently connected to the motor, providing a continuous phase shift that enhances efficiency.

**2. Applications in Ceiling and Exhaust Fans**

PSC capacitors are commonly used in ceiling fans and exhaust fans due to their ability to provide smooth and efficient operation. They are particularly effective in applications where variable speed control is required.

**3. Advantages and Disadvantages**

The advantages of PSC capacitors include energy efficiency, low maintenance, and quiet operation. However, they may not provide the same starting torque as other types of capacitors, which can be a disadvantage in certain applications.

B. Dual Run Capacitor

**1. Definition and Functionality**

A Dual Run Capacitor combines two capacitors in one housing, allowing it to serve both starting and running functions for two different motors. This design is particularly useful in HVAC systems where multiple fan motors are used.

**2. Use in HVAC Systems and Multiple Fan Motors**

Dual Run Capacitors are commonly found in air conditioning units and heat pumps, where they help manage the operation of both the compressor and the fan motor.

**3. Pros and Cons**

The primary advantage of Dual Run Capacitors is their space-saving design, which reduces the need for multiple components. However, if one side of the capacitor fails, it can affect the operation of both motors.

C. Start Capacitor

**1. Purpose and Operation**

Start capacitors are designed to provide a temporary boost of energy to start a motor. They are typically used in single-phase motors, where a high starting torque is required.

**2. Common Applications in Single-Phase Motors**

Start capacitors are commonly found in applications such as air compressors, refrigeration units, and some types of fans.

**3. Benefits and Limitations**

The main benefit of start capacitors is their ability to provide a high starting torque, allowing motors to start under heavy loads. However, they are only used for a short duration and must be disconnected once the motor reaches its operating speed.

D. Run Capacitor

**1. Explanation of Its Role in Continuous Operation**

Run capacitors are designed to remain in the circuit during the entire operation of the motor. They help maintain a consistent flow of energy, improving the motor's efficiency and performance.

**2. Typical Uses in Various Fan Types**

Run capacitors are commonly used in ceiling fans, HVAC systems, and other applications where continuous operation is required.

**3. Advantages and Disadvantages**

The advantages of run capacitors include improved efficiency and reduced energy consumption. However, they can be susceptible to failure over time, leading to decreased performance.

E. Capacitor-Start Capacitor-Run (CSCR)

**1. Overview of the CSCR Design**

The Capacitor-Start Capacitor-Run (CSCR) design combines both starting and running capacitors in a single unit. This design allows for high starting torque and efficient continuous operation.

**2. Applications in High-Efficiency Fans**

CSCR capacitors are commonly used in high-efficiency fans and motors, where both starting and running performance are critical.

**3. Benefits and Challenges**

The benefits of CSCR capacitors include improved efficiency and performance. However, they can be more complex and expensive than other types of capacitors.

IV. Key Features of Fan Capacitors

A. Voltage Ratings

**1. Importance of Selecting the Right Voltage**

Selecting the correct voltage rating for a fan capacitor is crucial for ensuring safe and efficient operation. Using a capacitor with an incorrect voltage rating can lead to failure or damage to the motor.

**2. Common Voltage Ratings for Fan Capacitors**

Common voltage ratings for fan capacitors include 250V, 370V, and 440V, depending on the application and motor specifications.

B. Capacitance Values

**1. Understanding Microfarads (µF)**

Capacitance is measured in microfarads (µF), and it indicates the capacitor's ability to store electrical energy. The capacitance value must match the motor's requirements for optimal performance.

**2. How Capacitance Affects Fan Performance**

Higher capacitance values can provide more starting torque, while lower values may be suitable for continuous operation. Selecting the right capacitance is essential for achieving the desired performance.

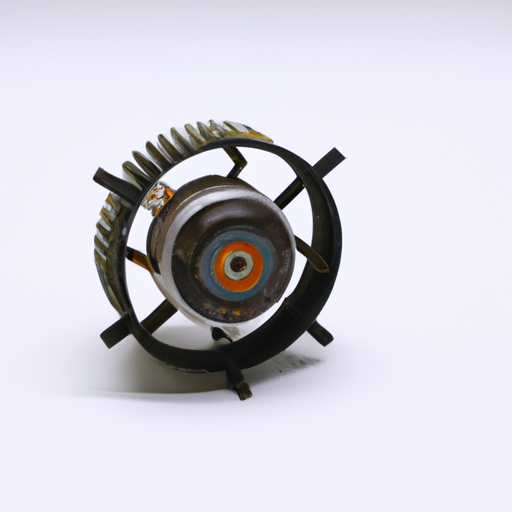

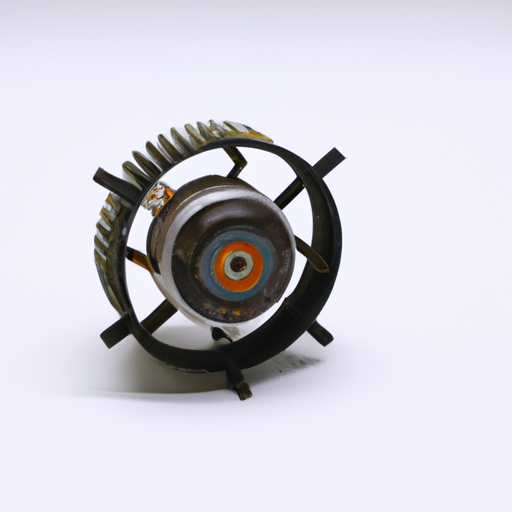

C. Physical Characteristics

**1. Size and Shape Considerations**

The physical size and shape of a fan capacitor can vary based on its type and application. It's important to ensure that the capacitor fits within the designated space in the fan or motor.

**2. Material Types and Their Impact on Durability**

Capacitors can be made from various materials, including aluminum and plastic. The choice of materials can impact the capacitor's durability and lifespan.

V. Selecting the Right Fan Capacitor

A. Factors to Consider

**1. Compatibility with Fan Type and Motor**

When selecting a fan capacitor, it's essential to ensure compatibility with the specific fan type and motor. This includes considering the voltage rating, capacitance value, and physical dimensions.

**2. Environmental Conditions and Operating Conditions**

Environmental factors, such as temperature and humidity, can affect capacitor performance. It's important to choose a capacitor that can withstand the operating conditions of the application.

B. Common Mistakes to Avoid

**1. Misjudging Voltage and Capacitance**

One of the most common mistakes is misjudging the voltage and capacitance requirements. Always refer to the manufacturer's specifications to avoid compatibility issues.

**2. Ignoring Manufacturer Specifications**

Ignoring manufacturer specifications can lead to poor performance and potential damage to the motor. Always follow the guidelines provided by the manufacturer when selecting a capacitor.

VI. Maintenance and Troubleshooting

A. Signs of a Failing Capacitor

**1. Symptoms of Malfunctioning Fans**

Common symptoms of a failing capacitor include unusual noises, reduced airflow, and the fan not starting or stopping unexpectedly. If you notice these signs, it may be time to inspect the capacitor.

**2. How to Diagnose Capacitor Issues**

Diagnosing capacitor issues typically involves checking for visible signs of damage, such as bulging or leaking. Additionally, using a multimeter can help test the capacitor's functionality.

B. Maintenance Tips for Longevity

**1. Regular Inspections and Testing**

Regular inspections and testing can help identify potential issues before they become serious problems. It's advisable to check capacitors periodically, especially in high-use applications.

**2. Best Practices for Replacement**

When replacing a capacitor, always ensure that the new component matches the specifications of the original. Proper installation and securing connections can also help extend the lifespan of the new capacitor.

VII. Conclusion

In summary, fan capacitors are vital components that enhance the performance and efficiency of fans and motors. Understanding the different types of fan capacitors, their features, and how to select and maintain them is essential for anyone involved in electrical systems. By choosing the right capacitor and following best practices for maintenance, users can ensure optimal performance and longevity of their fans.

VIII. References

For further reading and resources on fan capacitors, consider exploring industry standards and guidelines, as well as manufacturer specifications. Understanding these resources can provide valuable insights into the proper use and maintenance of fan capacitors.

What are the Popular Fan Capacitor Product Types?

I. Introduction

Fan capacitors are essential components in various electrical systems, particularly in fans and motors. They play a crucial role in enhancing the performance and efficiency of these devices. Understanding the different types of fan capacitors and their applications can help consumers and technicians make informed decisions when selecting or replacing these components. This article aims to provide a comprehensive overview of fan capacitors, their types, features, selection criteria, and maintenance tips.

II. Understanding Fan Capacitors

A. What is a Capacitor?

At its core, a capacitor is an electrical component that stores and releases electrical energy. It consists of two conductive plates separated by an insulating material, known as a dielectric. The basic principle of capacitance is the ability of a capacitor to store an electric charge. When voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy.

Capacitors play a vital role in electrical circuits by smoothing out voltage fluctuations, filtering signals, and providing the necessary phase shift in alternating current (AC) applications. In the context of fans, capacitors are crucial for starting and running the motors efficiently.

B. Specific Function of Fan Capacitors

Fan capacitors serve two primary functions: starting and running. Starting capacitors provide the initial boost of energy needed to start the motor, while running capacitors maintain the motor's operation by ensuring a consistent flow of energy. By enhancing the performance of fans, these capacitors contribute to improved efficiency, reduced energy consumption, and extended motor life.

III. Types of Fan Capacitors

A. Permanent Split Capacitor (PSC)

**1. Description and Working Principle**

Permanent Split Capacitor (PSC) motors are designed with a capacitor that remains in the circuit during both starting and running phases. This type of capacitor is permanently connected to the motor, providing a continuous phase shift that enhances efficiency.

**2. Applications in Ceiling and Exhaust Fans**

PSC capacitors are commonly used in ceiling fans and exhaust fans due to their ability to provide smooth and efficient operation. They are particularly effective in applications where variable speed control is required.

**3. Advantages and Disadvantages**

The advantages of PSC capacitors include energy efficiency, low maintenance, and quiet operation. However, they may not provide the same starting torque as other types of capacitors, which can be a disadvantage in certain applications.

B. Dual Run Capacitor

**1. Definition and Functionality**

A Dual Run Capacitor combines two capacitors in one housing, allowing it to serve both starting and running functions for two different motors. This design is particularly useful in HVAC systems where multiple fan motors are used.

**2. Use in HVAC Systems and Multiple Fan Motors**

Dual Run Capacitors are commonly found in air conditioning units and heat pumps, where they help manage the operation of both the compressor and the fan motor.

**3. Pros and Cons**

The primary advantage of Dual Run Capacitors is their space-saving design, which reduces the need for multiple components. However, if one side of the capacitor fails, it can affect the operation of both motors.

C. Start Capacitor

**1. Purpose and Operation**

Start capacitors are designed to provide a temporary boost of energy to start a motor. They are typically used in single-phase motors, where a high starting torque is required.

**2. Common Applications in Single-Phase Motors**

Start capacitors are commonly found in applications such as air compressors, refrigeration units, and some types of fans.

**3. Benefits and Limitations**

The main benefit of start capacitors is their ability to provide a high starting torque, allowing motors to start under heavy loads. However, they are only used for a short duration and must be disconnected once the motor reaches its operating speed.

D. Run Capacitor

**1. Explanation of Its Role in Continuous Operation**

Run capacitors are designed to remain in the circuit during the entire operation of the motor. They help maintain a consistent flow of energy, improving the motor's efficiency and performance.

**2. Typical Uses in Various Fan Types**

Run capacitors are commonly used in ceiling fans, HVAC systems, and other applications where continuous operation is required.

**3. Advantages and Disadvantages**

The advantages of run capacitors include improved efficiency and reduced energy consumption. However, they can be susceptible to failure over time, leading to decreased performance.

E. Capacitor-Start Capacitor-Run (CSCR)

**1. Overview of the CSCR Design**

The Capacitor-Start Capacitor-Run (CSCR) design combines both starting and running capacitors in a single unit. This design allows for high starting torque and efficient continuous operation.

**2. Applications in High-Efficiency Fans**

CSCR capacitors are commonly used in high-efficiency fans and motors, where both starting and running performance are critical.

**3. Benefits and Challenges**

The benefits of CSCR capacitors include improved efficiency and performance. However, they can be more complex and expensive than other types of capacitors.

IV. Key Features of Fan Capacitors

A. Voltage Ratings

**1. Importance of Selecting the Right Voltage**

Selecting the correct voltage rating for a fan capacitor is crucial for ensuring safe and efficient operation. Using a capacitor with an incorrect voltage rating can lead to failure or damage to the motor.

**2. Common Voltage Ratings for Fan Capacitors**

Common voltage ratings for fan capacitors include 250V, 370V, and 440V, depending on the application and motor specifications.

B. Capacitance Values

**1. Understanding Microfarads (µF)**

Capacitance is measured in microfarads (µF), and it indicates the capacitor's ability to store electrical energy. The capacitance value must match the motor's requirements for optimal performance.

**2. How Capacitance Affects Fan Performance**

Higher capacitance values can provide more starting torque, while lower values may be suitable for continuous operation. Selecting the right capacitance is essential for achieving the desired performance.

C. Physical Characteristics

**1. Size and Shape Considerations**

The physical size and shape of a fan capacitor can vary based on its type and application. It's important to ensure that the capacitor fits within the designated space in the fan or motor.

**2. Material Types and Their Impact on Durability**

Capacitors can be made from various materials, including aluminum and plastic. The choice of materials can impact the capacitor's durability and lifespan.

V. Selecting the Right Fan Capacitor

A. Factors to Consider

**1. Compatibility with Fan Type and Motor**

When selecting a fan capacitor, it's essential to ensure compatibility with the specific fan type and motor. This includes considering the voltage rating, capacitance value, and physical dimensions.

**2. Environmental Conditions and Operating Conditions**

Environmental factors, such as temperature and humidity, can affect capacitor performance. It's important to choose a capacitor that can withstand the operating conditions of the application.

B. Common Mistakes to Avoid

**1. Misjudging Voltage and Capacitance**

One of the most common mistakes is misjudging the voltage and capacitance requirements. Always refer to the manufacturer's specifications to avoid compatibility issues.

**2. Ignoring Manufacturer Specifications**

Ignoring manufacturer specifications can lead to poor performance and potential damage to the motor. Always follow the guidelines provided by the manufacturer when selecting a capacitor.

VI. Maintenance and Troubleshooting

A. Signs of a Failing Capacitor

**1. Symptoms of Malfunctioning Fans**

Common symptoms of a failing capacitor include unusual noises, reduced airflow, and the fan not starting or stopping unexpectedly. If you notice these signs, it may be time to inspect the capacitor.

**2. How to Diagnose Capacitor Issues**

Diagnosing capacitor issues typically involves checking for visible signs of damage, such as bulging or leaking. Additionally, using a multimeter can help test the capacitor's functionality.

B. Maintenance Tips for Longevity

**1. Regular Inspections and Testing**

Regular inspections and testing can help identify potential issues before they become serious problems. It's advisable to check capacitors periodically, especially in high-use applications.

**2. Best Practices for Replacement**

When replacing a capacitor, always ensure that the new component matches the specifications of the original. Proper installation and securing connections can also help extend the lifespan of the new capacitor.

VII. Conclusion

In summary, fan capacitors are vital components that enhance the performance and efficiency of fans and motors. Understanding the different types of fan capacitors, their features, and how to select and maintain them is essential for anyone involved in electrical systems. By choosing the right capacitor and following best practices for maintenance, users can ensure optimal performance and longevity of their fans.

VIII. References

For further reading and resources on fan capacitors, consider exploring industry standards and guidelines, as well as manufacturer specifications. Understanding these resources can provide valuable insights into the proper use and maintenance of fan capacitors.