Important Product Categories of DC Resistors

I. Introduction

A. Definition of DC Resistors

DC resistors are passive electronic components that resist the flow of direct current (DC) in a circuit. They are fundamental to the operation of electronic devices, serving various functions such as limiting current, dividing voltages, and providing biasing for active components. Resistors are characterized by their resistance value, which is measured in ohms (Ω), and they play a crucial role in controlling electrical signals.

B. Importance of DC Resistors in Electronic Circuits

In electronic circuits, DC resistors are essential for ensuring proper functionality and stability. They help manage the flow of current, protect sensitive components from excessive current, and enable the design of complex circuits. Without resistors, circuits would be prone to malfunction, overheating, or even damage. Their versatility and reliability make them indispensable in a wide range of applications, from consumer electronics to industrial machinery.

C. Overview of the Article

This article will explore the important product categories of DC resistors, including their types, key characteristics, applications, and selection criteria. By understanding these aspects, engineers and designers can make informed decisions when choosing resistors for their specific needs.

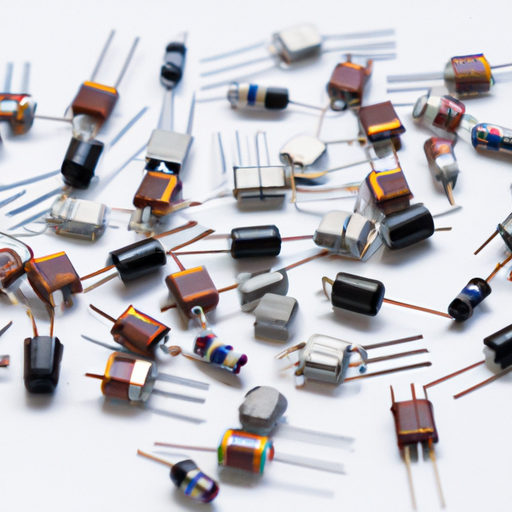

II. Types of DC Resistors

DC resistors can be broadly categorized into three main types: fixed resistors, variable resistors, and specialty resistors. Each category serves distinct purposes and is designed for specific applications.

A. Fixed Resistors

Fixed resistors have a predetermined resistance value that does not change. They are widely used in various electronic circuits.

1. Carbon Composition Resistors

Carbon composition resistors are made from a mixture of carbon particles and a binding resin. They are known for their low cost and ability to withstand high energy pulses. However, they have a relatively high tolerance and are less stable over time compared to other types.

2. Metal Film Resistors

Metal film resistors are constructed using a thin film of metal deposited on a ceramic substrate. They offer high precision, low noise, and excellent temperature stability. These resistors are commonly used in applications requiring accurate resistance values, such as in audio equipment and precision measurement devices.

3. Carbon Film Resistors

Carbon film resistors are similar to metal film resistors but use a carbon film instead. They provide better performance than carbon composition resistors in terms of stability and tolerance. Carbon film resistors are often used in general-purpose applications.

4. Wirewound Resistors

Wirewound resistors are made by winding a metal wire around a ceramic or fiberglass core. They can handle high power ratings and are often used in applications where heat dissipation is critical, such as in power supplies and amplifiers.

B. Variable Resistors

Variable resistors allow for adjustable resistance values, making them suitable for applications where fine-tuning is necessary.

1. Potentiometers

Potentiometers are three-terminal devices that can vary resistance by adjusting a sliding contact along a resistive element. They are commonly used in volume controls, tuning circuits, and as adjustable voltage dividers.

2. Rheostats

Rheostats are similar to potentiometers but are typically used to control higher currents. They have two terminals and are often employed in applications such as dimmer switches and motor speed controls.

C. Specialty Resistors

Specialty resistors are designed for specific applications and often have unique characteristics.

1. Current Sensing Resistors

Current sensing resistors are low-resistance components used to measure current flow in a circuit. They are essential in applications such as battery management systems and power monitoring.

2. High Voltage Resistors

High voltage resistors are designed to operate safely at elevated voltage levels. They are used in applications such as power supplies and high-voltage testing equipment.

3. Precision Resistors

Precision resistors are manufactured to have very tight tolerances and temperature coefficients. They are critical in applications requiring high accuracy, such as in instrumentation and calibration.

III. Key Characteristics of DC Resistors

When selecting DC resistors, several key characteristics must be considered to ensure optimal performance in a given application.

A. Resistance Value

The resistance value, measured in ohms, determines how much current will flow through the resistor when a voltage is applied. It is crucial to select the appropriate resistance value to achieve the desired circuit behavior.

B. Power Rating

The power rating indicates the maximum amount of power the resistor can dissipate without overheating. It is essential to choose a resistor with a power rating that exceeds the expected power dissipation in the circuit to prevent failure.

C. Tolerance

Tolerance refers to the allowable deviation from the specified resistance value. Resistors are available in various tolerances, with lower tolerances providing greater accuracy. Selecting the right tolerance is vital for applications requiring precise resistance values.

D. Temperature Coefficient

The temperature coefficient indicates how much the resistance value changes with temperature. Resistors with low temperature coefficients are preferred in applications where temperature variations are expected, as they maintain stability over a range of conditions.

E. Voltage Rating

The voltage rating specifies the maximum voltage that can be applied across the resistor without risking breakdown. It is important to choose a resistor with a voltage rating that exceeds the maximum voltage in the circuit.

IV. Applications of DC Resistors

DC resistors find applications across various industries and sectors, each with unique requirements.

A. Consumer Electronics

In consumer electronics, resistors are used in devices such as televisions, radios, and smartphones. They help control audio levels, manage power distribution, and ensure signal integrity.

B. Industrial Equipment

Industrial equipment relies on resistors for controlling motors, sensors, and other components. They play a critical role in automation systems, process control, and machinery operation.

C. Automotive Applications

In the automotive industry, resistors are used in various systems, including engine control units, lighting, and infotainment systems. They help manage power distribution and ensure the proper functioning of electronic components.

D. Telecommunications

Telecommunications equipment utilizes resistors for signal conditioning, impedance matching, and power management. They are essential in maintaining signal quality and reliability in communication systems.

E. Medical Devices

In medical devices, precision and reliability are paramount. Resistors are used in diagnostic equipment, monitoring devices, and therapeutic systems to ensure accurate measurements and safe operation.

V. Selection Criteria for DC Resistors

When selecting DC resistors for a specific application, several criteria should be considered to ensure optimal performance.

A. Application Requirements

Understanding the specific requirements of the application is crucial. Factors such as resistance value, power rating, and tolerance must align with the circuit's needs.

B. Environmental Considerations

Environmental factors, such as temperature, humidity, and exposure to chemicals, can impact resistor performance. Selecting resistors that can withstand the operating environment is essential for long-term reliability.

C. Cost vs. Performance

Balancing cost and performance is a critical consideration. While high-precision resistors may offer better performance, they can also be more expensive. Evaluating the trade-offs is necessary to make informed decisions.

D. Availability and Supply Chain Factors

The availability of specific resistor types and their lead times can impact project timelines. Ensuring that the selected resistors can be sourced reliably is essential for successful project execution.

VI. Conclusion

A. Recap of the Importance of DC Resistors

DC resistors are fundamental components in electronic circuits, playing a vital role in controlling current, managing voltage, and ensuring the stability of devices. Understanding the different types of resistors and their characteristics is essential for engineers and designers.

B. Future Trends in DC Resistor Technology

As technology advances, the demand for more precise and reliable resistors continues to grow. Innovations in materials and manufacturing processes are expected to lead to the development of resistors with improved performance characteristics, such as lower temperature coefficients and higher power ratings.

C. Final Thoughts on Choosing the Right Resistor for Applications

Choosing the right DC resistor involves careful consideration of various factors, including application requirements, environmental conditions, and cost. By understanding the different product categories and their characteristics, engineers can make informed decisions that enhance the performance and reliability of their electronic circuits.

VII. References

A. Suggested Reading

1. "Electronic Components: A Complete Reference for Engineers and Technicians" by John Doe

2. "The Art of Electronics" by Paul Horowitz and Winfield Hill

B. Industry Standards and Guidelines

1. IEC 60115 - Resistors for use in electronic equipment

2. EIA-198 - Standard for Resistor Specifications

C. Manufacturer Resources

1. Vishay Intertechnology - Resistor Product Catalog

2. Yageo Corporation - Resistor Selection Guide

This comprehensive overview of DC resistors highlights their importance, types, characteristics, applications, and selection criteria, providing valuable insights for anyone involved in electronic design and engineering.

Important Product Categories of DC Resistors

I. Introduction

A. Definition of DC Resistors

DC resistors are passive electronic components that resist the flow of direct current (DC) in a circuit. They are fundamental to the operation of electronic devices, serving various functions such as limiting current, dividing voltages, and providing biasing for active components. Resistors are characterized by their resistance value, which is measured in ohms (Ω), and they play a crucial role in controlling electrical signals.

B. Importance of DC Resistors in Electronic Circuits

In electronic circuits, DC resistors are essential for ensuring proper functionality and stability. They help manage the flow of current, protect sensitive components from excessive current, and enable the design of complex circuits. Without resistors, circuits would be prone to malfunction, overheating, or even damage. Their versatility and reliability make them indispensable in a wide range of applications, from consumer electronics to industrial machinery.

C. Overview of the Article

This article will explore the important product categories of DC resistors, including their types, key characteristics, applications, and selection criteria. By understanding these aspects, engineers and designers can make informed decisions when choosing resistors for their specific needs.

II. Types of DC Resistors

DC resistors can be broadly categorized into three main types: fixed resistors, variable resistors, and specialty resistors. Each category serves distinct purposes and is designed for specific applications.

A. Fixed Resistors

Fixed resistors have a predetermined resistance value that does not change. They are widely used in various electronic circuits.

1. Carbon Composition Resistors

Carbon composition resistors are made from a mixture of carbon particles and a binding resin. They are known for their low cost and ability to withstand high energy pulses. However, they have a relatively high tolerance and are less stable over time compared to other types.

2. Metal Film Resistors

Metal film resistors are constructed using a thin film of metal deposited on a ceramic substrate. They offer high precision, low noise, and excellent temperature stability. These resistors are commonly used in applications requiring accurate resistance values, such as in audio equipment and precision measurement devices.

3. Carbon Film Resistors

Carbon film resistors are similar to metal film resistors but use a carbon film instead. They provide better performance than carbon composition resistors in terms of stability and tolerance. Carbon film resistors are often used in general-purpose applications.

4. Wirewound Resistors

Wirewound resistors are made by winding a metal wire around a ceramic or fiberglass core. They can handle high power ratings and are often used in applications where heat dissipation is critical, such as in power supplies and amplifiers.

B. Variable Resistors

Variable resistors allow for adjustable resistance values, making them suitable for applications where fine-tuning is necessary.

1. Potentiometers

Potentiometers are three-terminal devices that can vary resistance by adjusting a sliding contact along a resistive element. They are commonly used in volume controls, tuning circuits, and as adjustable voltage dividers.

2. Rheostats

Rheostats are similar to potentiometers but are typically used to control higher currents. They have two terminals and are often employed in applications such as dimmer switches and motor speed controls.

C. Specialty Resistors

Specialty resistors are designed for specific applications and often have unique characteristics.

1. Current Sensing Resistors

Current sensing resistors are low-resistance components used to measure current flow in a circuit. They are essential in applications such as battery management systems and power monitoring.

2. High Voltage Resistors

High voltage resistors are designed to operate safely at elevated voltage levels. They are used in applications such as power supplies and high-voltage testing equipment.

3. Precision Resistors

Precision resistors are manufactured to have very tight tolerances and temperature coefficients. They are critical in applications requiring high accuracy, such as in instrumentation and calibration.

III. Key Characteristics of DC Resistors

When selecting DC resistors, several key characteristics must be considered to ensure optimal performance in a given application.

A. Resistance Value

The resistance value, measured in ohms, determines how much current will flow through the resistor when a voltage is applied. It is crucial to select the appropriate resistance value to achieve the desired circuit behavior.

B. Power Rating

The power rating indicates the maximum amount of power the resistor can dissipate without overheating. It is essential to choose a resistor with a power rating that exceeds the expected power dissipation in the circuit to prevent failure.

C. Tolerance

Tolerance refers to the allowable deviation from the specified resistance value. Resistors are available in various tolerances, with lower tolerances providing greater accuracy. Selecting the right tolerance is vital for applications requiring precise resistance values.

D. Temperature Coefficient

The temperature coefficient indicates how much the resistance value changes with temperature. Resistors with low temperature coefficients are preferred in applications where temperature variations are expected, as they maintain stability over a range of conditions.

E. Voltage Rating

The voltage rating specifies the maximum voltage that can be applied across the resistor without risking breakdown. It is important to choose a resistor with a voltage rating that exceeds the maximum voltage in the circuit.

IV. Applications of DC Resistors

DC resistors find applications across various industries and sectors, each with unique requirements.

A. Consumer Electronics

In consumer electronics, resistors are used in devices such as televisions, radios, and smartphones. They help control audio levels, manage power distribution, and ensure signal integrity.

B. Industrial Equipment

Industrial equipment relies on resistors for controlling motors, sensors, and other components. They play a critical role in automation systems, process control, and machinery operation.

C. Automotive Applications

In the automotive industry, resistors are used in various systems, including engine control units, lighting, and infotainment systems. They help manage power distribution and ensure the proper functioning of electronic components.

D. Telecommunications

Telecommunications equipment utilizes resistors for signal conditioning, impedance matching, and power management. They are essential in maintaining signal quality and reliability in communication systems.

E. Medical Devices

In medical devices, precision and reliability are paramount. Resistors are used in diagnostic equipment, monitoring devices, and therapeutic systems to ensure accurate measurements and safe operation.

V. Selection Criteria for DC Resistors

When selecting DC resistors for a specific application, several criteria should be considered to ensure optimal performance.

A. Application Requirements

Understanding the specific requirements of the application is crucial. Factors such as resistance value, power rating, and tolerance must align with the circuit's needs.

B. Environmental Considerations

Environmental factors, such as temperature, humidity, and exposure to chemicals, can impact resistor performance. Selecting resistors that can withstand the operating environment is essential for long-term reliability.

C. Cost vs. Performance

Balancing cost and performance is a critical consideration. While high-precision resistors may offer better performance, they can also be more expensive. Evaluating the trade-offs is necessary to make informed decisions.

D. Availability and Supply Chain Factors

The availability of specific resistor types and their lead times can impact project timelines. Ensuring that the selected resistors can be sourced reliably is essential for successful project execution.

VI. Conclusion

A. Recap of the Importance of DC Resistors

DC resistors are fundamental components in electronic circuits, playing a vital role in controlling current, managing voltage, and ensuring the stability of devices. Understanding the different types of resistors and their characteristics is essential for engineers and designers.

B. Future Trends in DC Resistor Technology

As technology advances, the demand for more precise and reliable resistors continues to grow. Innovations in materials and manufacturing processes are expected to lead to the development of resistors with improved performance characteristics, such as lower temperature coefficients and higher power ratings.

C. Final Thoughts on Choosing the Right Resistor for Applications

Choosing the right DC resistor involves careful consideration of various factors, including application requirements, environmental conditions, and cost. By understanding the different product categories and their characteristics, engineers can make informed decisions that enhance the performance and reliability of their electronic circuits.

VII. References

A. Suggested Reading

1. "Electronic Components: A Complete Reference for Engineers and Technicians" by John Doe

2. "The Art of Electronics" by Paul Horowitz and Winfield Hill

B. Industry Standards and Guidelines

1. IEC 60115 - Resistors for use in electronic equipment

2. EIA-198 - Standard for Resistor Specifications

C. Manufacturer Resources

1. Vishay Intertechnology - Resistor Product Catalog

2. Yageo Corporation - Resistor Selection Guide

This comprehensive overview of DC resistors highlights their importance, types, characteristics, applications, and selection criteria, providing valuable insights for anyone involved in electronic design and engineering.