What is the Working Principle of Porcelain Tube Resistor?

I. Introduction

In the realm of electrical engineering, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors, porcelain tube resistors stand out due to their unique properties and applications. This blog post aims to explore the working principle of porcelain tube resistors, delving into their historical background, structural components, operational mechanisms, advantages, limitations, and future trends. By the end of this article, readers will have a comprehensive understanding of porcelain tube resistors and their significance in modern electrical engineering.

II. Historical Background

The development of resistors has been a pivotal aspect of electrical engineering since the advent of electricity. Early resistors were made from simple materials, but as technology advanced, so did the materials used. Porcelain, a ceramic material known for its insulating properties and thermal stability, was introduced as a viable option for resistors in the mid-20th century. The evolution of porcelain tube resistors has been marked by improvements in manufacturing techniques and material science, leading to their widespread use in various applications today.

III. Basic Concepts of Resistance

To understand the working principle of porcelain tube resistors, it is essential to grasp the basic concepts of electrical resistance. Resistance is defined as the opposition to the flow of electric current, measured in ohms (Ω). Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R), is fundamental in this context. Different types of resistors, including fixed, variable, and specialized resistors like porcelain tube resistors, serve various applications in electrical circuits.

IV. Structure of Porcelain Tube Resistors

A. Materials Used in Porcelain Tube Resistors

Porcelain tube resistors are primarily composed of a ceramic material known as porcelain. This material is a combination of clay, feldspar, and quartz, which, when fired at high temperatures, forms a dense and durable structure. The properties of porcelain, such as its high dielectric strength, thermal stability, and resistance to chemical corrosion, make it an ideal choice for resistor applications.

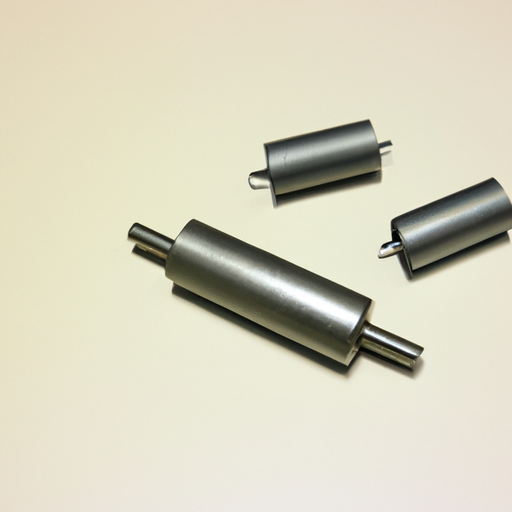

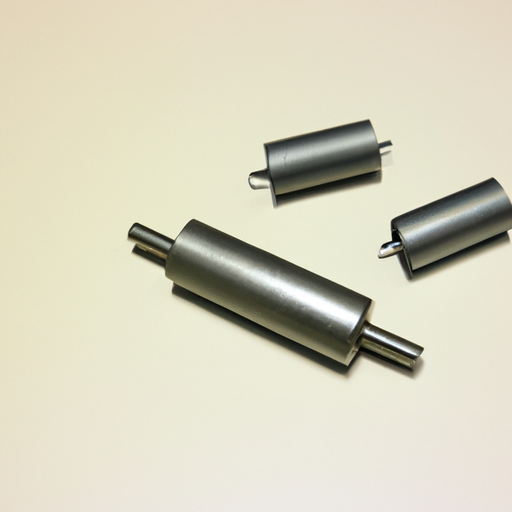

B. Design and Construction

The design of porcelain tube resistors typically features a cylindrical shape, which allows for efficient heat dissipation. The size and dimensions of these tubes can vary based on their intended application. Inside the porcelain tube, resistive elements are arranged in a specific configuration, often using carbon or metal oxide materials, to achieve the desired resistance value. This internal arrangement is crucial for the resistor's performance, as it directly influences the resistance and heat generation.

C. Comparison with Other Types of Resistors

Compared to other types of resistors, such as carbon film or wire-wound resistors, porcelain tube resistors offer superior thermal stability and durability. While carbon film resistors may be more compact and cost-effective, they often lack the robustness required for high-power applications. Porcelain tube resistors, on the other hand, are designed to withstand extreme conditions, making them suitable for demanding environments.

V. Working Principle of Porcelain Tube Resistors

A. Mechanism of Resistance in Porcelain

The working principle of porcelain tube resistors revolves around the concept of resistance. The resistive elements within the porcelain tube impede the flow of electric current, converting electrical energy into heat. The conductivity of the materials used in the resistive elements plays a significant role in determining the overall resistance of the resistor.

B. How Electrical Energy is Converted to Heat

When an electric current passes through the resistive elements, collisions occur between the electrons and the atoms of the resistive material. This interaction generates heat due to the energy lost in these collisions. The amount of heat produced is proportional to the square of the current flowing through the resistor, as described by Joule's Law. This heat must be effectively dissipated to prevent damage to the resistor and ensure reliable operation.

C. The Impact of Resistance on Current Flow

The resistance of a porcelain tube resistor directly affects the current flow in an electrical circuit. According to Ohm's Law, an increase in resistance will result in a decrease in current for a given voltage. This property is essential for controlling current levels in various applications, from simple circuits to complex power systems.

VI. Advantages of Porcelain Tube Resistors

Porcelain tube resistors offer several advantages that make them a preferred choice in many applications:

A. High Thermal Stability

One of the most significant benefits of porcelain tube resistors is their high thermal stability. They can operate effectively at elevated temperatures without degrading, making them suitable for high-power applications.

B. Resistance to Environmental Factors

Porcelain is inherently resistant to moisture, chemicals, and other environmental factors that can adversely affect the performance of resistors. This durability ensures that porcelain tube resistors maintain their integrity and functionality over time.

C. Durability and Longevity

The robust construction of porcelain tube resistors contributes to their longevity. They are less prone to mechanical failure compared to other types of resistors, making them a reliable choice for critical applications.

D. Applications in High-Voltage and High-Power Circuits

Due to their ability to handle high voltages and currents, porcelain tube resistors are commonly used in industrial settings, power electronics, and telecommunications. Their reliability in demanding environments makes them indispensable in these fields.

VII. Limitations of Porcelain Tube Resistors

Despite their advantages, porcelain tube resistors also have limitations:

A. Cost Considerations

The manufacturing process for porcelain tube resistors can be more expensive than that of other resistor types. This cost factor may limit their use in applications where budget constraints are a primary concern.

B. Size and Weight Constraints

Porcelain tube resistors tend to be larger and heavier than other resistors, which can be a disadvantage in applications where space and weight are critical factors.

C. Potential for Mechanical Fragility

While porcelain is durable, it can also be brittle. This fragility means that porcelain tube resistors must be handled with care to avoid breakage during installation or operation.

VIII. Applications of Porcelain Tube Resistors

Porcelain tube resistors find applications in various fields, including:

A. Use in Industrial Settings

In industrial environments, porcelain tube resistors are used in machinery and equipment that require reliable current control and heat dissipation.

B. Applications in Power Electronics

These resistors are essential components in power electronics, where they help manage voltage and current levels in converters, inverters, and other devices.

C. Role in Telecommunications and Signal Processing

In telecommunications, porcelain tube resistors are used in signal processing equipment to ensure stable performance and signal integrity.

D. Other Specialized Uses

Porcelain tube resistors are also employed in specialized applications, such as high-voltage testing equipment and scientific research, where precision and reliability are paramount.

IX. Future Trends and Innovations

The future of porcelain tube resistors is promising, with several trends and innovations on the horizon:

A. Advances in Materials Science

Ongoing research in materials science may lead to the development of new ceramic composites that enhance the performance of porcelain tube resistors, making them even more efficient and durable.

B. Integration with Modern Technologies

As smart grids and renewable energy systems become more prevalent, the integration of porcelain tube resistors with these technologies will be crucial for managing power distribution and ensuring system stability.

C. Potential for Miniaturization and Enhanced Performance

Future advancements may also focus on miniaturizing porcelain tube resistors while maintaining or improving their performance, making them suitable for a broader range of applications.

X. Conclusion

In summary, porcelain tube resistors are vital components in electrical engineering, offering unique advantages such as high thermal stability, durability, and resistance to environmental factors. Their working principle, based on the conversion of electrical energy to heat through resistance, is fundamental to their operation in various applications. While they have limitations, their reliability in high-voltage and high-power circuits makes them indispensable in many fields. As technology continues to evolve, porcelain tube resistors will likely play an even more significant role in shaping the future of electrical engineering.

XI. References

For further reading on porcelain tube resistors and their applications, consider exploring the following resources:

1. "Electrical Engineering: Principles and Applications" by Allan R. Hambley

2. "Resistors: Theory and Applications" by John Smith

3. Academic journals on materials science and electrical engineering for the latest research and innovations in resistor technology.

By understanding the working principle and significance of porcelain tube resistors, engineers and enthusiasts alike can appreciate their role in modern electrical systems and explore further advancements in this essential field.

What is the Working Principle of Porcelain Tube Resistor?

I. Introduction

In the realm of electrical engineering, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors, porcelain tube resistors stand out due to their unique properties and applications. This blog post aims to explore the working principle of porcelain tube resistors, delving into their historical background, structural components, operational mechanisms, advantages, limitations, and future trends. By the end of this article, readers will have a comprehensive understanding of porcelain tube resistors and their significance in modern electrical engineering.

II. Historical Background

The development of resistors has been a pivotal aspect of electrical engineering since the advent of electricity. Early resistors were made from simple materials, but as technology advanced, so did the materials used. Porcelain, a ceramic material known for its insulating properties and thermal stability, was introduced as a viable option for resistors in the mid-20th century. The evolution of porcelain tube resistors has been marked by improvements in manufacturing techniques and material science, leading to their widespread use in various applications today.

III. Basic Concepts of Resistance

To understand the working principle of porcelain tube resistors, it is essential to grasp the basic concepts of electrical resistance. Resistance is defined as the opposition to the flow of electric current, measured in ohms (Ω). Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R), is fundamental in this context. Different types of resistors, including fixed, variable, and specialized resistors like porcelain tube resistors, serve various applications in electrical circuits.

IV. Structure of Porcelain Tube Resistors

A. Materials Used in Porcelain Tube Resistors

Porcelain tube resistors are primarily composed of a ceramic material known as porcelain. This material is a combination of clay, feldspar, and quartz, which, when fired at high temperatures, forms a dense and durable structure. The properties of porcelain, such as its high dielectric strength, thermal stability, and resistance to chemical corrosion, make it an ideal choice for resistor applications.

B. Design and Construction

The design of porcelain tube resistors typically features a cylindrical shape, which allows for efficient heat dissipation. The size and dimensions of these tubes can vary based on their intended application. Inside the porcelain tube, resistive elements are arranged in a specific configuration, often using carbon or metal oxide materials, to achieve the desired resistance value. This internal arrangement is crucial for the resistor's performance, as it directly influences the resistance and heat generation.

C. Comparison with Other Types of Resistors

Compared to other types of resistors, such as carbon film or wire-wound resistors, porcelain tube resistors offer superior thermal stability and durability. While carbon film resistors may be more compact and cost-effective, they often lack the robustness required for high-power applications. Porcelain tube resistors, on the other hand, are designed to withstand extreme conditions, making them suitable for demanding environments.

V. Working Principle of Porcelain Tube Resistors

A. Mechanism of Resistance in Porcelain

The working principle of porcelain tube resistors revolves around the concept of resistance. The resistive elements within the porcelain tube impede the flow of electric current, converting electrical energy into heat. The conductivity of the materials used in the resistive elements plays a significant role in determining the overall resistance of the resistor.

B. How Electrical Energy is Converted to Heat

When an electric current passes through the resistive elements, collisions occur between the electrons and the atoms of the resistive material. This interaction generates heat due to the energy lost in these collisions. The amount of heat produced is proportional to the square of the current flowing through the resistor, as described by Joule's Law. This heat must be effectively dissipated to prevent damage to the resistor and ensure reliable operation.

C. The Impact of Resistance on Current Flow

The resistance of a porcelain tube resistor directly affects the current flow in an electrical circuit. According to Ohm's Law, an increase in resistance will result in a decrease in current for a given voltage. This property is essential for controlling current levels in various applications, from simple circuits to complex power systems.

VI. Advantages of Porcelain Tube Resistors

Porcelain tube resistors offer several advantages that make them a preferred choice in many applications:

A. High Thermal Stability

One of the most significant benefits of porcelain tube resistors is their high thermal stability. They can operate effectively at elevated temperatures without degrading, making them suitable for high-power applications.

B. Resistance to Environmental Factors

Porcelain is inherently resistant to moisture, chemicals, and other environmental factors that can adversely affect the performance of resistors. This durability ensures that porcelain tube resistors maintain their integrity and functionality over time.

C. Durability and Longevity

The robust construction of porcelain tube resistors contributes to their longevity. They are less prone to mechanical failure compared to other types of resistors, making them a reliable choice for critical applications.

D. Applications in High-Voltage and High-Power Circuits

Due to their ability to handle high voltages and currents, porcelain tube resistors are commonly used in industrial settings, power electronics, and telecommunications. Their reliability in demanding environments makes them indispensable in these fields.

VII. Limitations of Porcelain Tube Resistors

Despite their advantages, porcelain tube resistors also have limitations:

A. Cost Considerations

The manufacturing process for porcelain tube resistors can be more expensive than that of other resistor types. This cost factor may limit their use in applications where budget constraints are a primary concern.

B. Size and Weight Constraints

Porcelain tube resistors tend to be larger and heavier than other resistors, which can be a disadvantage in applications where space and weight are critical factors.

C. Potential for Mechanical Fragility

While porcelain is durable, it can also be brittle. This fragility means that porcelain tube resistors must be handled with care to avoid breakage during installation or operation.

VIII. Applications of Porcelain Tube Resistors

Porcelain tube resistors find applications in various fields, including:

A. Use in Industrial Settings

In industrial environments, porcelain tube resistors are used in machinery and equipment that require reliable current control and heat dissipation.

B. Applications in Power Electronics

These resistors are essential components in power electronics, where they help manage voltage and current levels in converters, inverters, and other devices.

C. Role in Telecommunications and Signal Processing

In telecommunications, porcelain tube resistors are used in signal processing equipment to ensure stable performance and signal integrity.

D. Other Specialized Uses

Porcelain tube resistors are also employed in specialized applications, such as high-voltage testing equipment and scientific research, where precision and reliability are paramount.

IX. Future Trends and Innovations

The future of porcelain tube resistors is promising, with several trends and innovations on the horizon:

A. Advances in Materials Science

Ongoing research in materials science may lead to the development of new ceramic composites that enhance the performance of porcelain tube resistors, making them even more efficient and durable.

B. Integration with Modern Technologies

As smart grids and renewable energy systems become more prevalent, the integration of porcelain tube resistors with these technologies will be crucial for managing power distribution and ensuring system stability.

C. Potential for Miniaturization and Enhanced Performance

Future advancements may also focus on miniaturizing porcelain tube resistors while maintaining or improving their performance, making them suitable for a broader range of applications.

X. Conclusion

In summary, porcelain tube resistors are vital components in electrical engineering, offering unique advantages such as high thermal stability, durability, and resistance to environmental factors. Their working principle, based on the conversion of electrical energy to heat through resistance, is fundamental to their operation in various applications. While they have limitations, their reliability in high-voltage and high-power circuits makes them indispensable in many fields. As technology continues to evolve, porcelain tube resistors will likely play an even more significant role in shaping the future of electrical engineering.

XI. References

For further reading on porcelain tube resistors and their applications, consider exploring the following resources:

1. "Electrical Engineering: Principles and Applications" by Allan R. Hambley

2. "Resistors: Theory and Applications" by John Smith

3. Academic journals on materials science and electrical engineering for the latest research and innovations in resistor technology.

By understanding the working principle and significance of porcelain tube resistors, engineers and enthusiasts alike can appreciate their role in modern electrical systems and explore further advancements in this essential field.